Cleaning

A total solution for controlling chemical, gas, vacuum and pneumatic pressure is proposed from utility to machines in semiconductor manufacturing.

View catalogDeposition, Etching, Annealing

Deposition: We offer products that can control process gas and vacuum with high accuracy. We also offer high-value gas supply components for ALD process, one of the most advanced process, with high durability, high temperature, high flow and high responsiveness. In addition, vacuum pressure control components helps you establish your process with high-precision.

Etching: CKD’s Process Gas Supply System, Flow Monitoring System, etc., contribute to leading edge etching process establishment.

Annealing: CKD provides units that integrates control valves and peripherals for controlling inert gases such as nitrogen and argon. We also offer you a comprehensive supply system of high-flow gas which is especially required in the annealing equipment. Sensors for inert gas flow is also available.

View catalogResist coating, Developiing, Exposure, Polishing, Resist stripping

Resist coating: Our high-performance chemical devices meet your needs in the process of resist coating that requires to uniform resist applying amount for refinement of a semiconductor circuit, to increase throughput and to reduce footprint.

Developing: With the refinement of semiconductor circuits, the process has been advancing, with the need to consistently dispense clean developing agents. Our highly reliable products help you realize these micro processes.

Exposure: We offer a wide range of line-up support for your equipment, including valves for control purposes such as pure water and N2 sensors used in the equipment. We will also be able to respond to changes in your request due to changes in light sources such as KrF, ArF, and EUV.

Polishing: We have a wide range of chemical control components that are essential for slurry and pure water control. We will help you reduce the size of your equipment offering the manifold support of the chemical valve.

Resist stripping: We provide both the chemical control components used in wet processes, such as SPM, and the gas control components used in dry processes which use gas and ozone (O3). It is a clean product that minimizes the risk of contamination into your processes. CKD provides total support, including pneumatic solenoid valves for controlling air operated valve.

View catalogIon implantation

We recommend stable supply of small flow gases and chamber vacuum pressure control, which are important in ion implantation. We offer a wide range of lineup, including gas control components, vacuum valves, air and N2 flow sensors. Please feel free to contact us all about the fluid controls .

View catalog-

MMD*03RN

Size : Size: φ6 to 25, 1/4" to 1"

operating and back pressure : 5 bar

Particle reduction, over-tightening prevention -

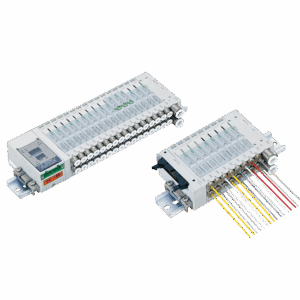

MN3E/MN4E

Size : Push-in φ1.8 to 6

Valve pitch : 7.0mm, 10mm

Solenoid valve for pilot air, PLC-compatible block manifold -

MNV

Size : 3/8"

Fluid temperature : 195℃

Particle reduction, stable flow rate, eNV -

MVB

Size : NW16 to 160

Body Material : alminum

High corrosion resistance, manual vacuum valve -

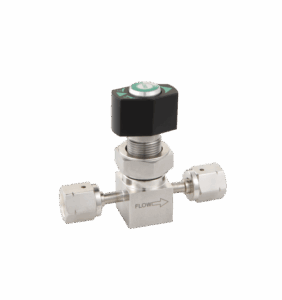

OGD

Size : 1/4", 3/8"

Fluid temperature : 5 to 80℃

Manual valve for process gas, 90°rotation snap-action -

PGM

Size : 1/4", 3/8", 1,125" & 1.5" for integrated system

Flow rate series : 20 to 200L/min

Regulator for process gas, particle reduction -

PMP

Size : Size: φ6 to 25, 1/4" to 1"

Set pressure : 0.2 to 3, 0.7 to 4 bar

Particle reduction, pilot regulator, high precision